Vacuum Casting/Silicone Mold

Small batch and low-volume production

Producing silicone casts

Silicone moulded parts can be created for prototypes, in small batches, and for low-volume production. The following pieces of information will help you decide how you will want to produce your silicone parts:

3D Printing of Silicone Parts

Many projects require multiple prototypes be made quickly. If you need 1-20 simple silicone casts made in just 24-48 hours, call us and explore what 3D silicone printing by TOP Proto can do for you.

Silicone Casting

Using non-metallic moulds, high-quality silicone castings can be produced using a range of colours. For a dozen to a few hundred units, silicone casting offers a less-expensive option when compared to producing metal parts.

Silicone Moulding

When you need high-quality prototype parts made in small quantities, liquid silicone rubber (LSR) moulding is the fast and economical solution. A single silicone mould can be reused, producing up to 50 identical casts quickly saving time and money – parts are easily reproduced without additional tooling or design.

The Advantages of Vacuum Casting

Vacuum casting is an economical alternative to low-volume injection molding of plastic parts and can be used to closely simulate final molded parts or finished products. It’s benefit to make plastic prototypes with this process.

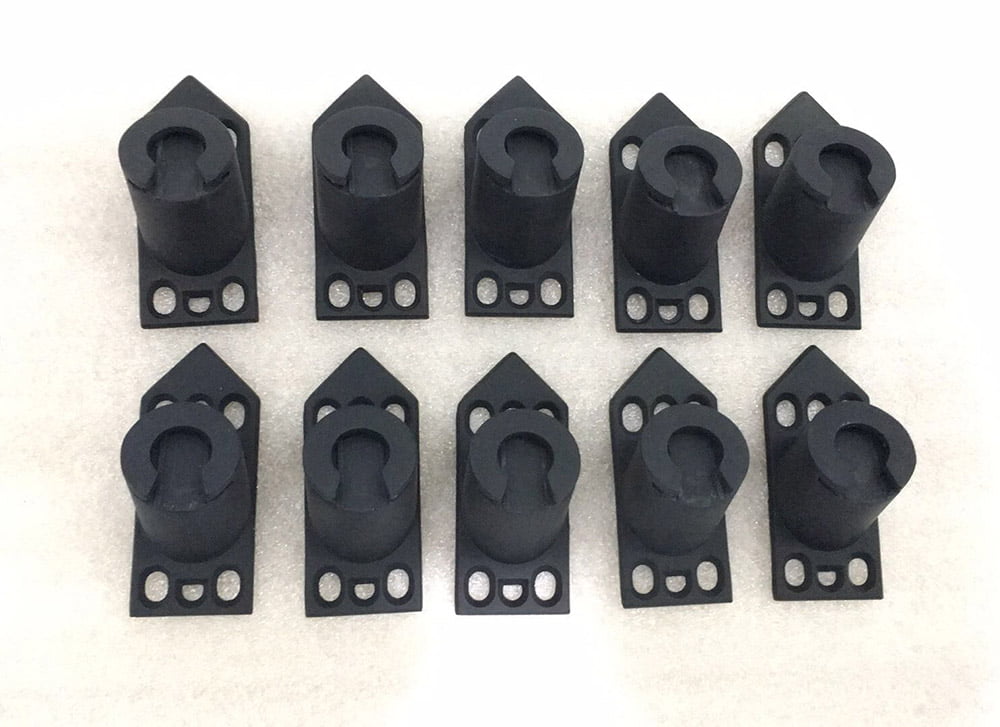

Vacuum casting parts we made

Vacuum Casting Materials

There are hundreds of casting polymers that are commercially available that fit the requirements for vacuum casting. They have the surface texture and hardness that you might be looking for. You can also make parts of different transparencies. Whether it’s translucent, transparent, or opaque, it all depends on how these parts will be used.

At TOP Proto, you can choose from any of the following materials:

The dimensions of the finished vacuum cast parts will depend on the accuracy of the master pattern, the types of casting material, and the geometry of the design. Generally, the shrinkage rate of these finished parts is not higher than 0.15%.

REQUEST A QUOTE NOW

All information will be secured and confidential