3D Printing

SLA, SLS and SLM Rapid Printing Services

SLA 3D PRINTING

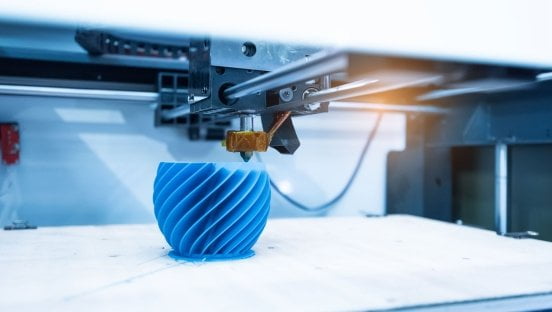

SLA (Stereo lithography Appearance) printing is applicable to presentation prototypes, concept models, and translucent prototypes. To create parts, the process cures the photopolymer layer by layer by UV light. SLA technology becomes popular because of the result of high resolution.

SLS 3D PRINTING

SLS ( Selective Laser Sintering) printing fuse the powder ( typically nylon powder ) to form the part by laser technology. Without additional supporting materials, the SLS printed parts allow high flexibility and are very suitable for functional parts and moving parts from prototypes. Parts can be assembled or joined.

SLM 3D PRINTING

We use SLM ( Selective Laser Melting ) to print metal parts. The metal powder will be melted and formed layer by layer to build the part. 3D printing manufacturing reduces materials waste and enhances the flexibility of the design. That’s why metal printing to be a popular alternative to machining services.

The Advantages of 3D Printing

Reduce Preparing Time

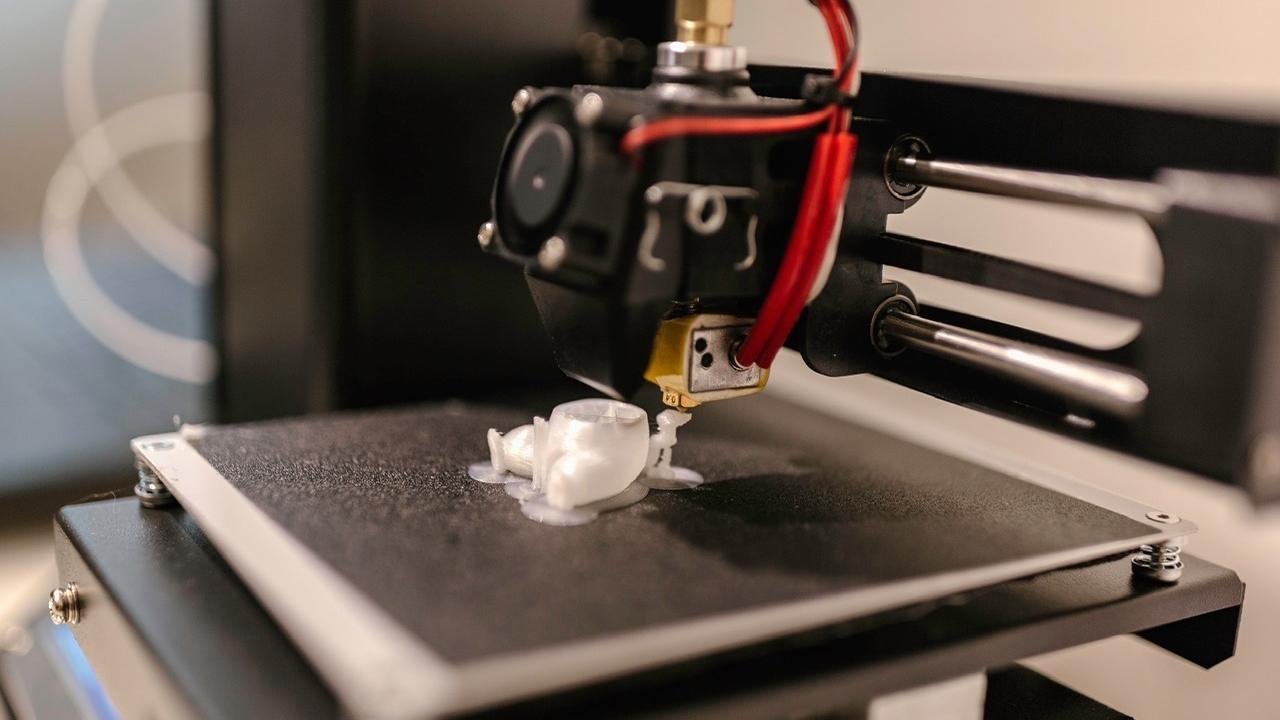

Unlike other machining processes, 3D printing do not need any support tools. It reduces the preparing time such as designing fixtures or adjusting the position in the machine. The liquid material is burned and built up the complex geometries in minutes.

Fast Turnaround

3D printing is a very fast manufacturing process. It’s ideal for the situation that customers need fast feedback at the very beginning of product development.

Flexible Manufacturing

For some complex shapes, CNC machining needs to use more than 2 machines to be achieved. However, 3D printing can be designed by the supports and build up the shape at one time.

Material Options

The most common 3D printing material is polylactic acid (PLA). It is a biodegradable plastic derived from renewable energy sources such as cornflour. Because of its low melting point, it is simple to utilize at home.

ABS is ideally suited for elements that require strength and flexibility.

Use for pre-assembled components, final goods, and prototypes.

PC (Polycarbonate):

Polycarbonate, a less common form of plastic than the others, can only be utilized in 3D printers with nozzle designs and high temperatures.

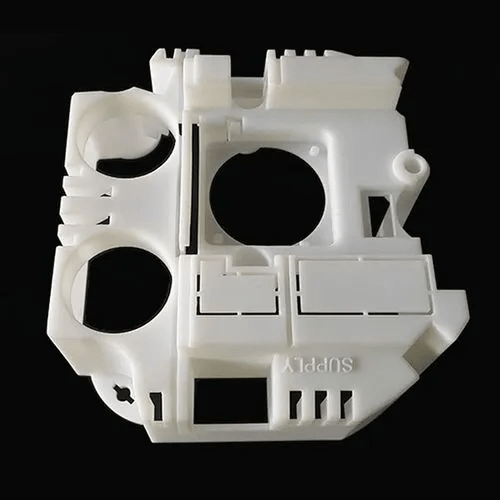

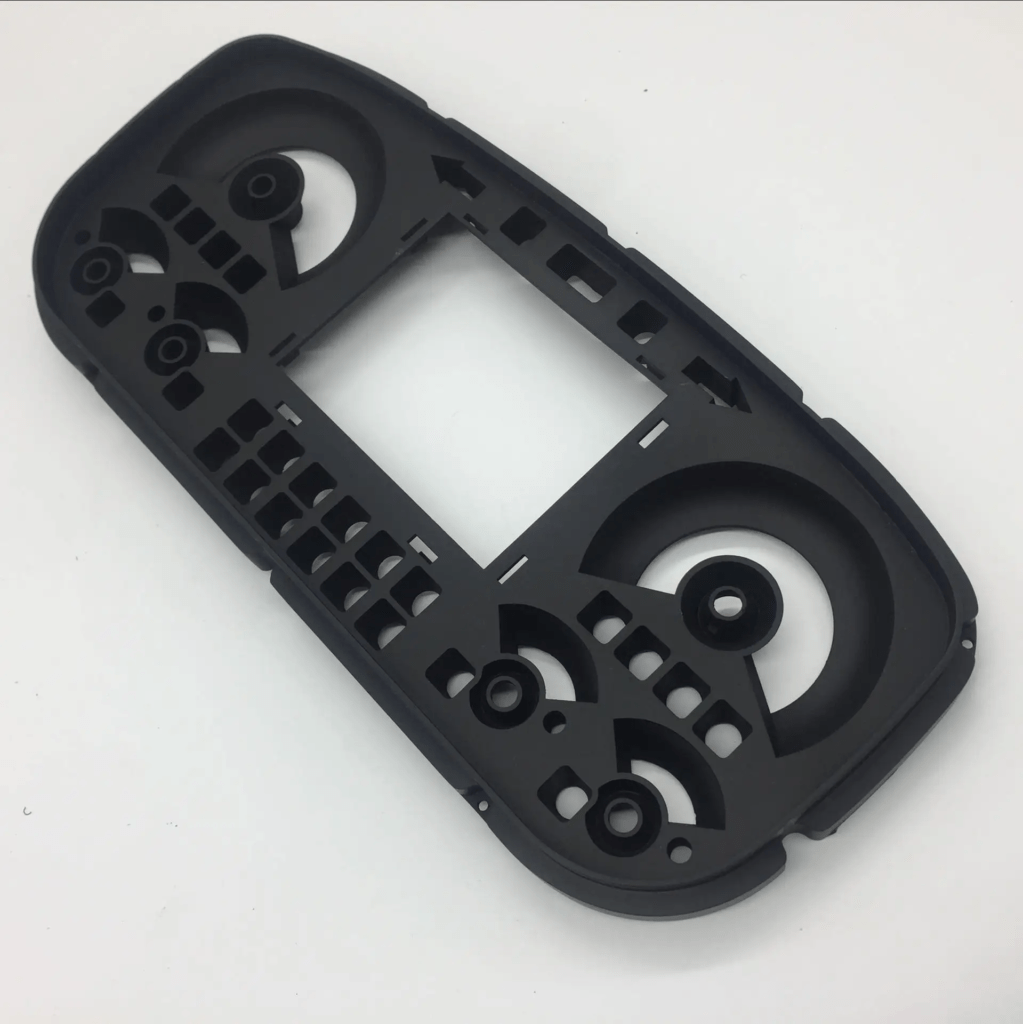

3D Printing parts we made

REQUEST A QUOTE NOW

All information will be secured and confidential