Sheet Metal Fabrication Services

We are providing Custom Sheet Metal Fabrication Services ( As Per Customer Need ) :

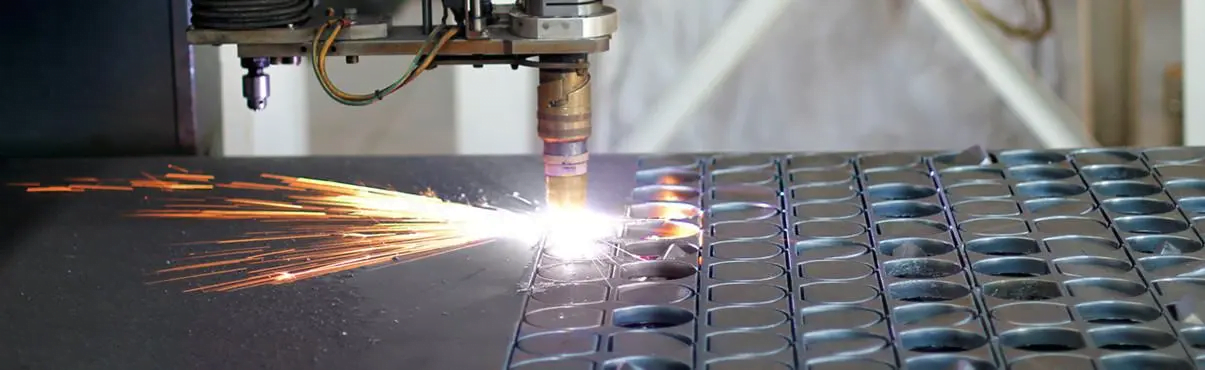

LASER CUTTING

Laser cutting is a precise and versatile method for cutting sheet metal with the help of a high-powered laser beam.

This process allows for intricate and complex shapes to be cut accurately, with minimal heat-affected zones and high cutting speeds.

Laser cutting is suitable for most of the material such as steel, aluminium, stainless steel, and others.

It is commonly used for applications that demand high precision, such as electronics enclosures, signage, brackets, and decorative panels.

STAMPING

Every press of the stamping machine goes through elastic deformation as the material has resistance to being deformed, the stamping must conquer the resistance and other forces.

The maximum tonnage that a press can withstand without compromising any of its components is called press tonnage capacity.

Metal material of stamping requires enough strength to support the finished products while remaining flexible for fluent geometry shape. Depending on the desired property of the finished parts, the metal used in stamping is usually in hardness grade from soft to medium.

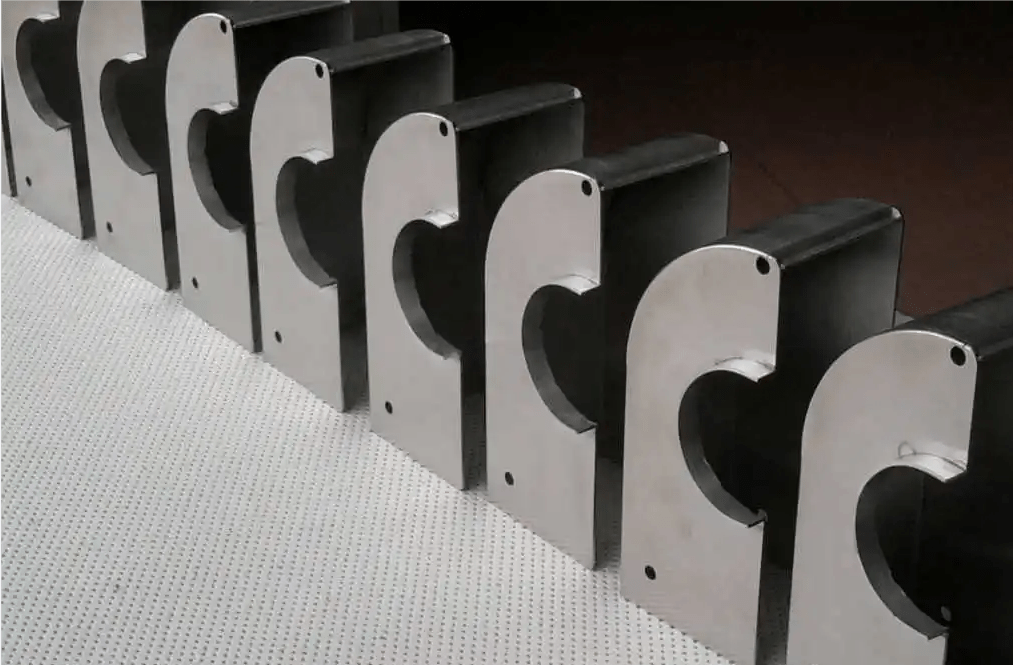

BENDING

Bending is a process that shapes sheet metal by applying force to deform it along a straight axis.

This is achieved using specialized machines such as press brakes.

Bending allows for the creation of various angles and complex geometries in sheet metal components.

HVAC (heating, ventilation, and air conditioning), automobile, aerospace, and appliance manufacture all use it extensively.

Our bending services ensure precise and accurate bending, meeting your specific design requirements.

The Advantages of Sheet Metal

Sheet metal fabrication serves a wide variety of applications. No matter what the nature, function and performance are, it would be the right position. For that, sheet metal fabrication is your better choice in some cases.

WHAT TYPES OF SHEET METAL CAN BE PRODUCED?

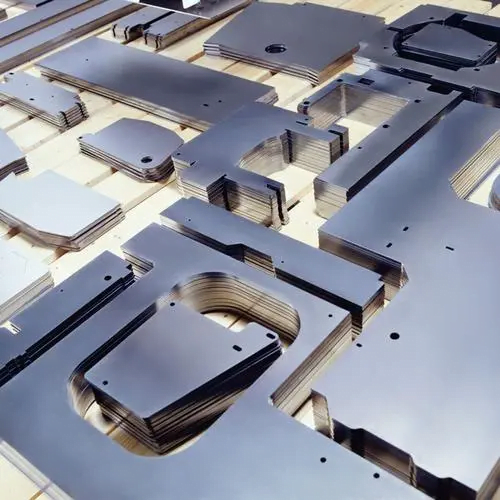

Parts made with sheet metal are exceptionally durable and versatile. Create a single prototype, or manufacture thousands of identical units using a variety of different metals including:

Strong and brilliant, sheet metals have both utility and decorative uses. Using superior raw materials sheet metals are pressed into coils, foils, or sheets of varying thickness then manufactured into your design.

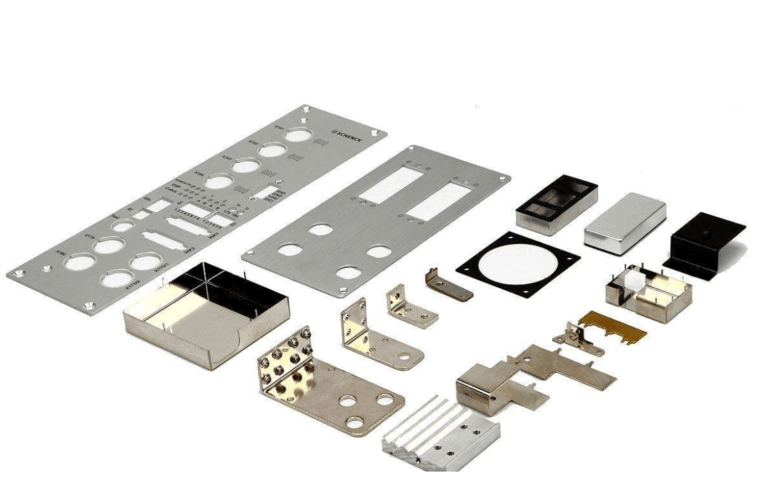

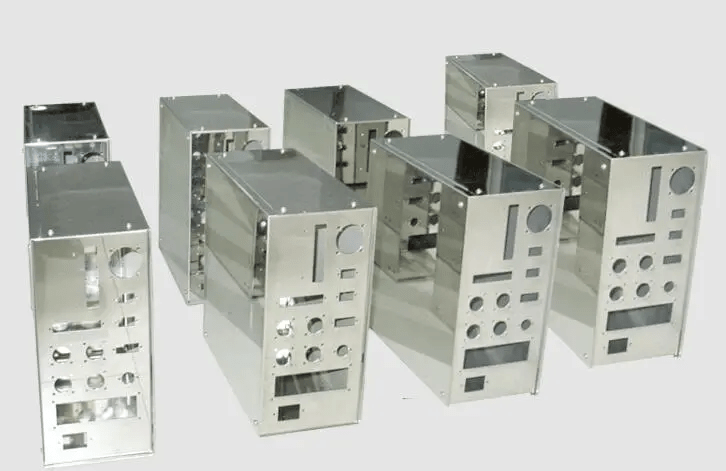

Sheet Metal Parts We Made

REQUEST A QUOTE NOW

All information will be secured and confidential